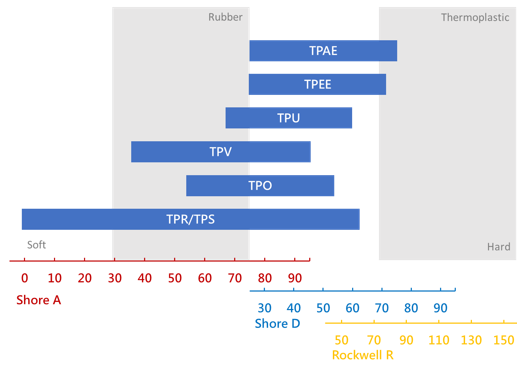

TPE hardness is typically measured using Shore Hardness by ASTM D2240 standards. Most TPEs are measured on the Shore A scale.

- For harder materials (above 90A), the Shore D scale is used for greater accuracy.

- For softer materials (below 10A), the Shore 00 scale is recommended.

When working with thermoplastic elastomers (TPE), hardness is one of the most critical performance indicators, as it directly affects comfort, functionality, and application suitability.

TPE hardness is typically measured using Shore Hardness by ASTM D2240 standards. Most TPEs are measured on the Shore A scale.

- For harder materials (above 90A), the Shore D scale is used for greater accuracy.

- For softer materials (below 10A), the Shore 00 scale is recommended.

| 熱塑性彈性體Thermoplastic elastomer TPE | ||||||||

| Materia type |

Styrenic Thermoplastic Elastomer TPS/TPR |

Thermoplastic Polyolefin TPO |

Thermoplastic Vulcanizate TPV |

Thermoplastic Polyurethane TPU |

Thermoplastic Polyester Elastomer TPEE |

Thermoplastic Polyamide Elastomer TPAE |

Acrylic Elastomer ACE |

Thermoplastic Silicone Vulcanizate TPSiV |

| Characteristic |

Wide Hardness Range | Excellent Chemical Resistance | Good Compression Set | Abrasion Resistance Puncture Resistance Moisture Vapor Transmission |

Resilience / Elastic Recovery Flex Fatigue Resistance |

Resilience / Elastic Recovery Flex Fatigue Resistance |

Transparency Self-Adhesion / Self-Bonding |

Skin-friendly & Smooth Touch |

TPE offers a variety of advantages, such as:

-

High elasticity

-

Non-slip properties

-

Soft and comfortable touch

-

Good chemical resistance

-

No vulcanization required

-

Directly injection moldable and recyclable

Thermoplastic elastomers (TPE) are functional materials that combine the elastic properties of rubber with the processing advantages of plastic.

Unlike traditional rubber, TPE can be processed using standard plastic methods such as injection molding, extrusion, and blow molding, without the need for vulcanization. This enables more efficient production, allowing the material to be recycled and reused.

TPE (Thermoplastic Elastomer) is a general term that encompasses various types of thermoplastic elastic materials.

TPR (Thermoplastic Rubber) typically refers to TPE-S, which is a styrenic-based type of TPE. It generally offers better elasticity and a softer touch, making it popular in toys and household products.

In simple terms, TPR is a subcategory of TPE.